Sustainable heat with wood pellets:

In harmony with climate protection and healthy forests

The forest is one of the most valuable resources on our planet. It not only provides a habitat for countless animal and plant species, but also plays a central role in the global climate system by storing carbon dioxide and producing oxygen.

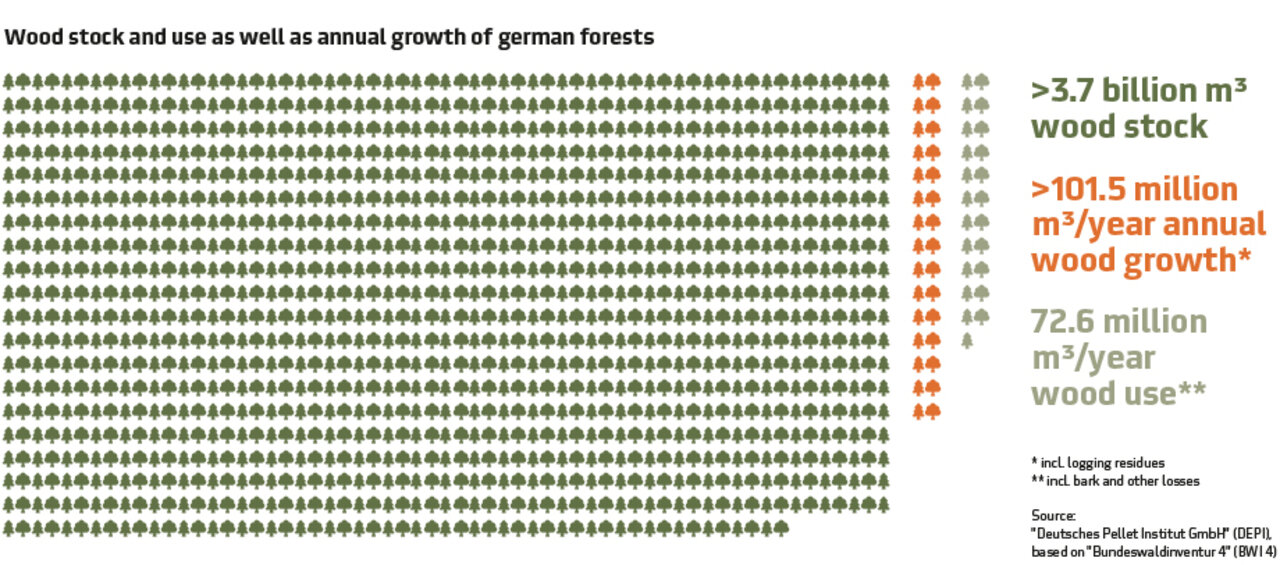

Wood, as a natural resource, can be used in many ways – it serves as a building material, energy source, and a base material for paper and furniture. Furthermore, the forest contributes to human recreation, promotes biodiversity, and protects against erosion and flooding. There is thus enormous potential for environmental protection and economic development in the sustainable use of forests and wood. Germany is one of the most forested countries in Europe. With about 30%, the forest covers a considerable area of the country.

About 122 cubic meters of wood grow in Germany each year, which is equivalent to a wood growth of 4 m³ per second. Only about two-thirds of that is used. Thus, the wood reserves are continuously increasing. As one of the largest private forest owners, we at LEAG take responsibility for healthy, diverse forests. Active forest conversion, away from aging, vulnerable monocultures and towards climate-stable mixed forests, offers the best protection against climate change. The material and energy use of the resulting wood volumes is an important prerequisite for this.

No tree is cut down specifically for wood pellets

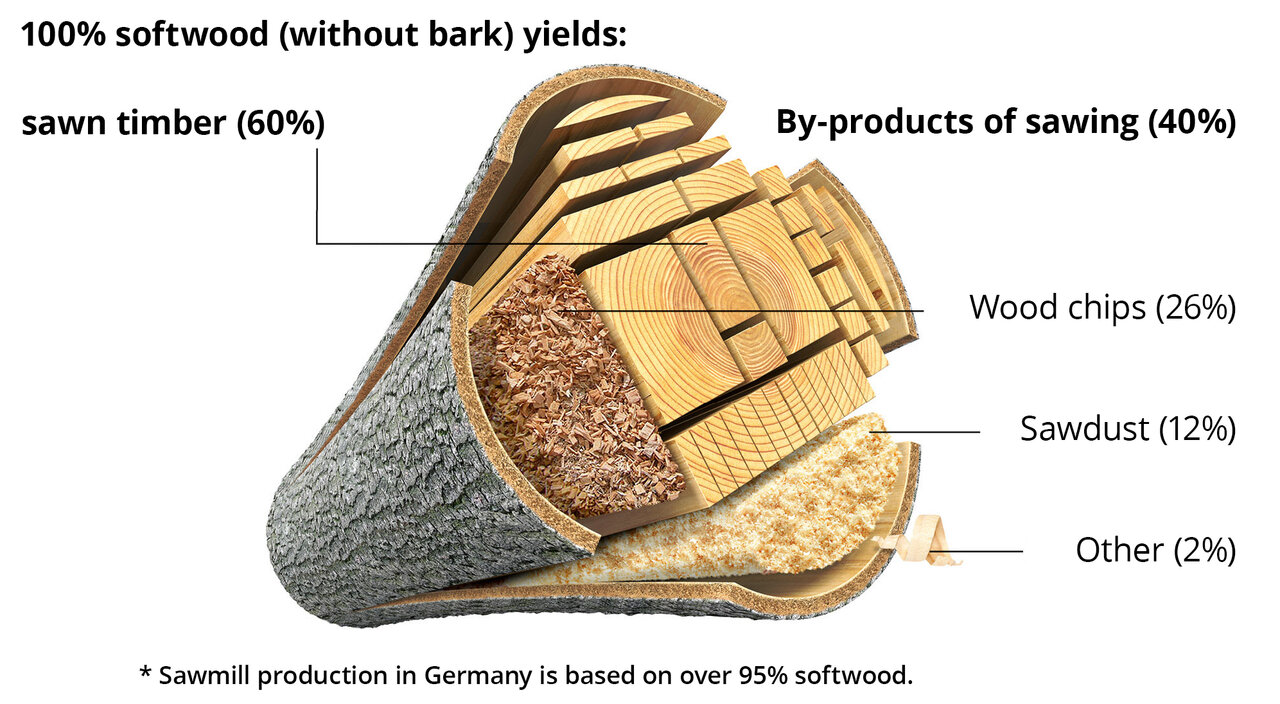

Our pellets are made from wood chips, wood shavings, and sawdust, which are by-products of sawmills and the furniture industry. When cutting round timber into boards, beams, and strips, about 40% of the wood remains as pelletizable sawmill residues.

Even residual wood from logging and thinning, such as crown and weak wood, as well as storm, damaged, or crooked wood, which is no longer suitable for processing in the sawmill, can be processed for pellet production. High-quality lumber is not processed into pellets, as the highest value added in the sawmill is in the lumber. The sole processing into wood pellets would be uneconomical. The material use of wood as a building material and its energetic use for heat supply are not in competition, but rather mutually dependent. Energy wood is a by-product of sustainable forestry and wood industry: If it is not used, it rots in the forest without achieving CO2 reduction!

Timber cutting in the sawmill

Heating with pellets in a climate-friendly way:

Great potential for the expansion of efficient wood heat

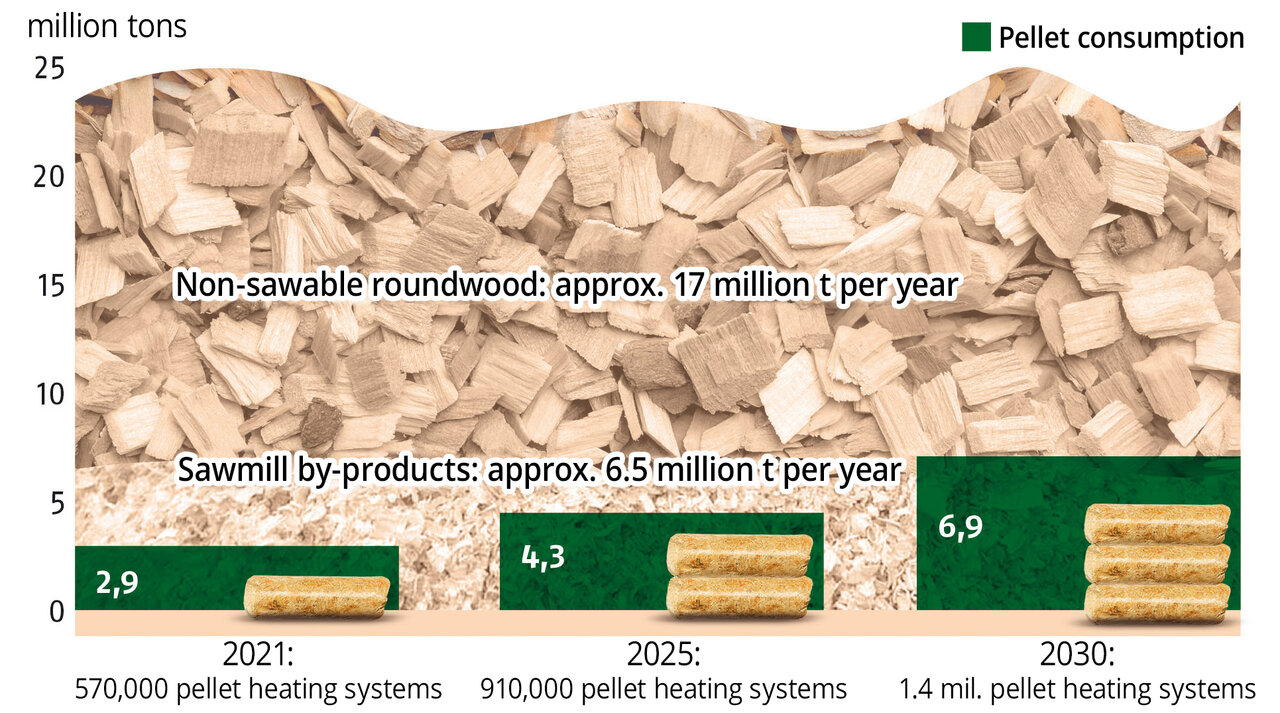

With over 20 million tons of pelletizable wood residues generated annually in Germany, there is still a gigantic potential available for the heat transition with wood pellets. Strict legal requirements for sustainability ensure that only as much wood is removed as can regrow. The clear-cutting of forests is prohibited by law.

Scenario: Availability of raw materials and the expansion of pellet heating systems

Guaranteed sustainable:

We are PEFC and SBP certified.

We set industry standards when it comes to the sustainability, transparency, and origin of our raw materials. With PEFC (Programme for the Endorsement of Forest Certification) and SBP (Sustainable Biomass Program) certifications, we meet strict requirements for sourcing raw materials from regional, secure sources. The internationally recognized certificates guarantee that wood and biomass products come from environmentally friendly managed forests that meet the highest ecological, social, and economic standards. Through independent inspections and comprehensive traceability, the systems create trust and transparency – from the forest to the final use. With our wood pellets, you not only heat efficiently and reliably, but also sustainably and environmentally friendly.

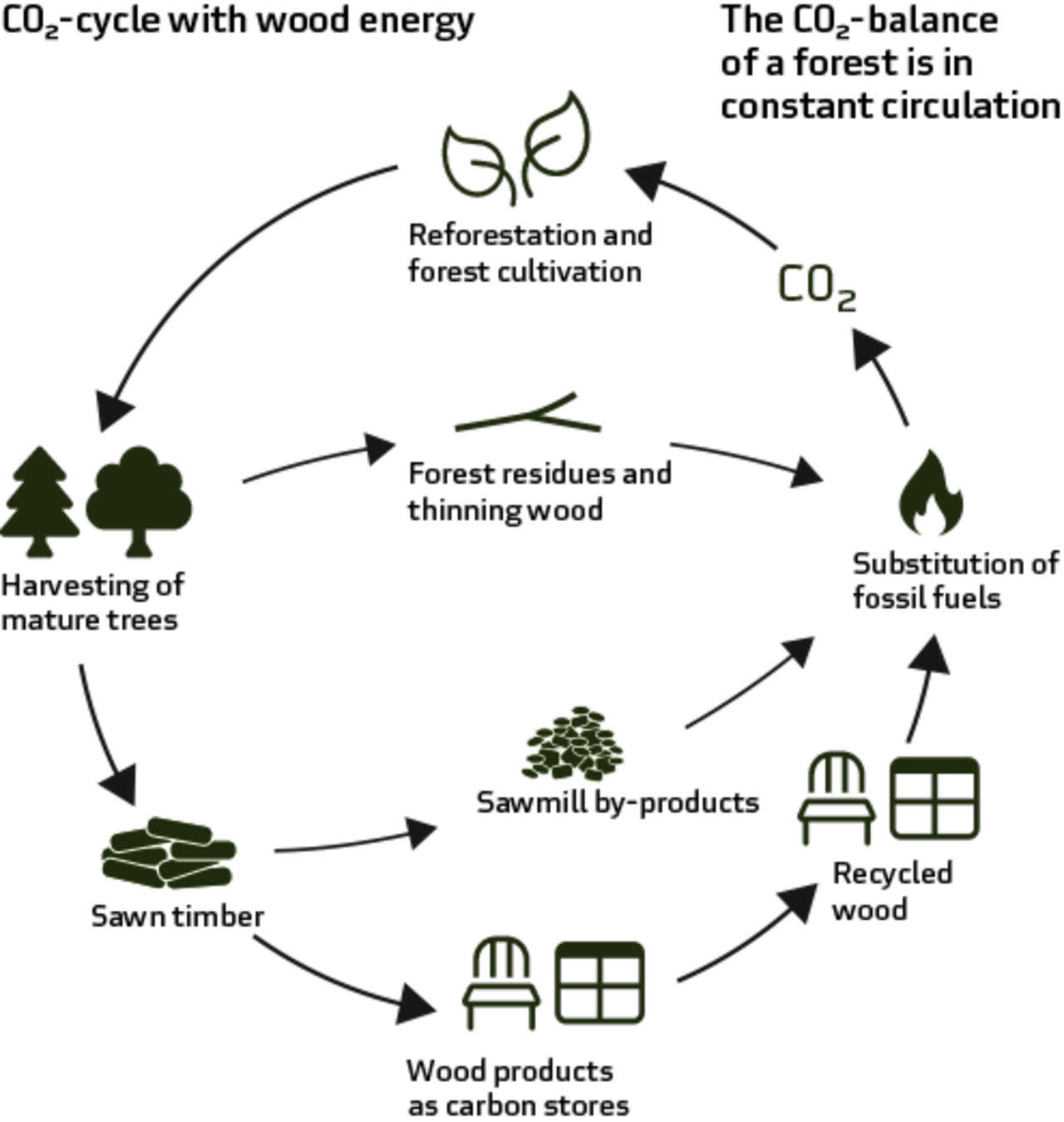

Therefore, heating with pellets is considered CO2-neutral.

When considering the forest as a CO2 storage, it is not the individual tree that counts, but the forest as a whole. The CO2 cycle refers to the entire stock, which includes new plantings and reforestation of harvested old stock, and plays an essential role.

Studies show that actively managed, constantly rejuvenating forests have a significantly better climate balance than old, 'abandoned' forests, as trees store the most carbon in the second age class (between the 15th and 40th year).

Active forestry management is a targeted approach to managing the structure of a forest, as the space for trees on the forest area is limited. In their quest for light, water, and nutrients, trees compete with one another.When a tree is removed, neighboring trees take advantage of the newly available space and compensate for the removal by growing more vigorously.

Depending on the tree species and yield, 50-80% of the wood is used for material purposes after harvesting, e.g. in wood construction, materials, insulation, etc. These wood products continue to serve as carbon storage. About one-third can be used for energy: The carbon is released in the exact amount that the tree absorbed during its growth. Therefore, it does not contribute to the CO2 enrichment in the atmosphere. On the contrary, the use of wood pellets for heat supply saves and avoids emissions from fossil sources (coal, oil, gas).

- Find out more: Link Our forest of the future

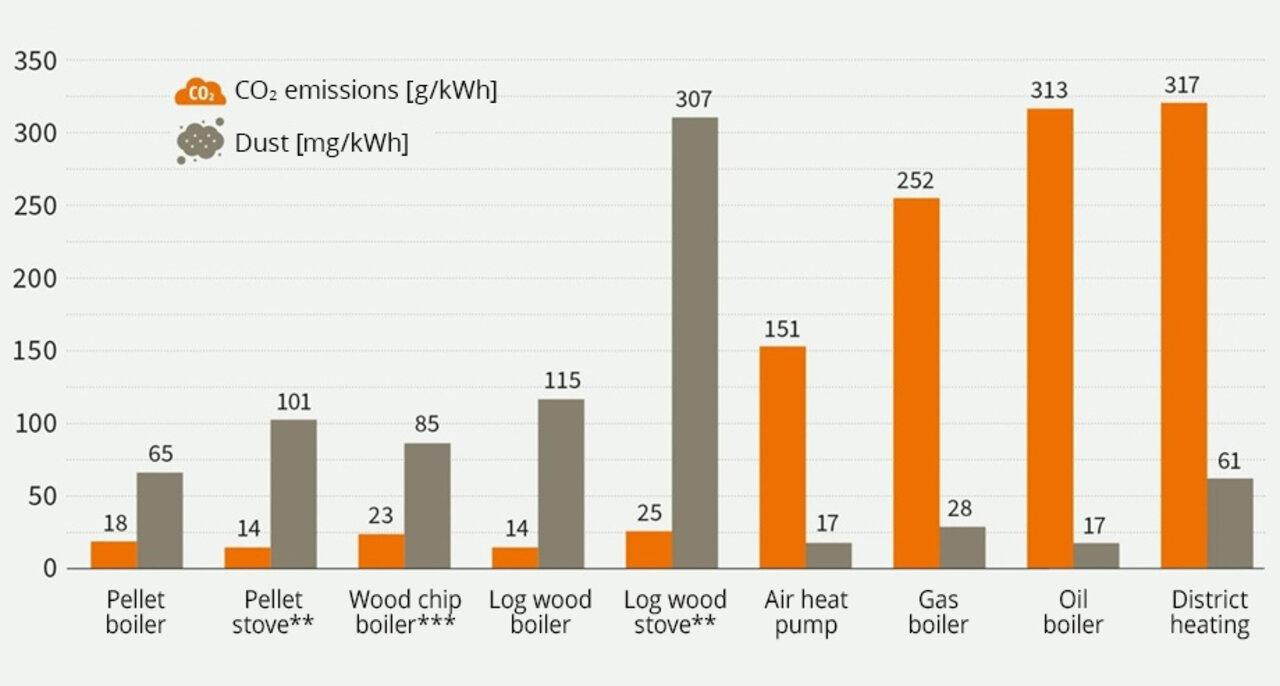

CO2 emissions of heating systems compared

A pellet heating system is currently the heating system with the lowest CO2 emissions compared to a heat pump, gas heating, or district heating.

Upstream emissions, which occur during logging, in the production process, or during transportation, are low due to regional value creation and are priced in Germany by the BEHG. The combustion process of wood pellets is CO2-neutral.

With about 18 g CO2 per kWh of energy, the pellet boiler is a true world champion. For comparison: an oil heating system emits around 313 g and even the heat pump 175 g/kWh, due to the fossil component in the electricity. Pellet heating systems also undercut all dust limits. Due to their high efficiency and clean combustion, modern pellet systems are comparable to a classic wood-burning stove.